- RealMan Robotic Arm RML63-B, 6 Degrees of Freedom, with Long Arm Span

- Payload: 3kg

- Features an ultra-lightweight humanoid robotic arm with long arm span

- Built-in safety module

- Provides faster returns on automation

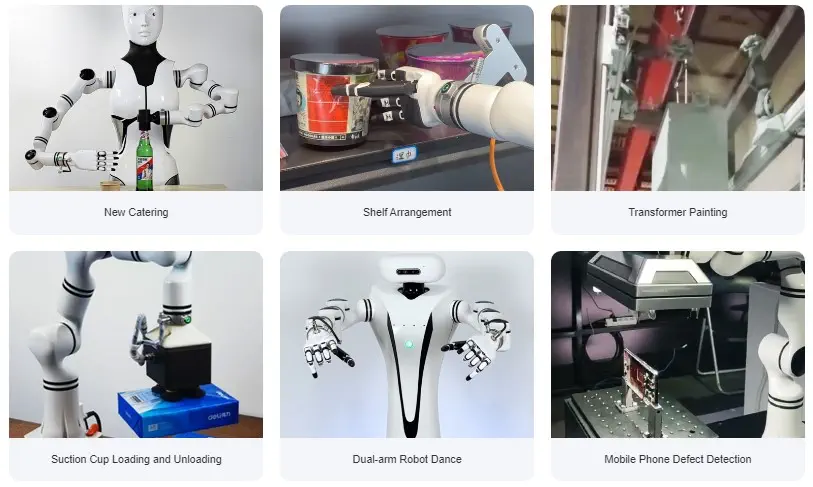

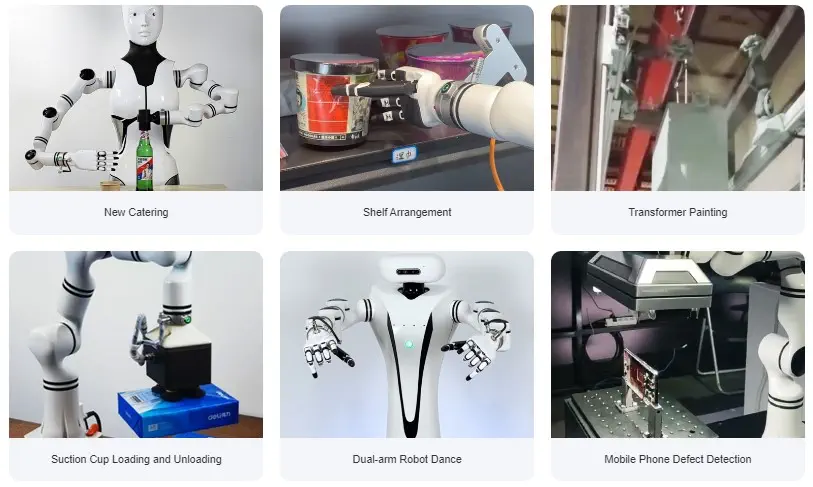

- Suitable for a wide range of scenarios

The RealMan Robotic Arm RML63-B, 6 DoF, 3kg Payload, Long Arm (Basic Version) is a basic version of the 6-dof long arm span robotic arm, is self-developed and produced by RealMan. The controller is integrated at the bottom of the robotic arm, lightweight, and flexible.

The modular joint design of the robotic arm enables sufficient workspace, meeting the requirements of more complex application scenarios. Maximum power consumption ≤200W, comprehensive power consumption ≤100W.

Integrated Modularization: Integrated and modular design, easier disassembly and assembly, lower maintenance costs, and higher efficiency.

Ultra-high Load-to-self-weight Ratio: Ultra-lightweight body, with the self-weight of the robotic arm (including controller) being only 10 kg, payload up to 5 kg, 1:1.3 load-to-self-weight ratio, and an effective working radius of up to 900 mm.

Flexible Deployment: Ultra-small volume, with a maximum robotic arm diameter of 11.5 cm and a base installation diameter of 11 cm. The size of the humanoid robotic arm greatly reduces the installation space requirements, making it more convenient and flexible.

Ultra-low Power: DC power supply of 24 V, suitable for mobile power supply, with a maximum power consumption of ≤ 200 W and a comprehensive power consumption of ≤ 100 W under full load, and can be applied in various scenarios.

Integrated Controller: No traditional control cabinet, perfectly integrating the controller with the robotic arm.

Ultra-high Compatibility: The end offers a general interface that is expandable and plug-and-play. The integrated robotic arm has rich interfaces to meet the expansion of application needs in a variety of industries.

Open System: Open API function library, supporting C/C++/C#/Python programming language, and supporting Windows/Linux/ROS robot operating systems and various communication protocols.

Safe and Sensitive: Sensitive drag and drop programming, which can fully reproduce the drag trajectory; The protection level can be set, and the robotic arm will stop immediately when the collision reaches the maximum torque limit, thereby avoiding injury to personnel or equ.

Wireless and Convenient Connection: Connection and control of the robotic arm by wired and wireless means, easy and quick switching, and liberation from the limits of control cables.