Payments and Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Description

- 2x HFmotor-40150 (150W) coreless DC motor

- Copley servo driver

- MOTC1 motor controller

- RHF407 development board

- ULB-16 ultrasonic rangefinders

PDF File

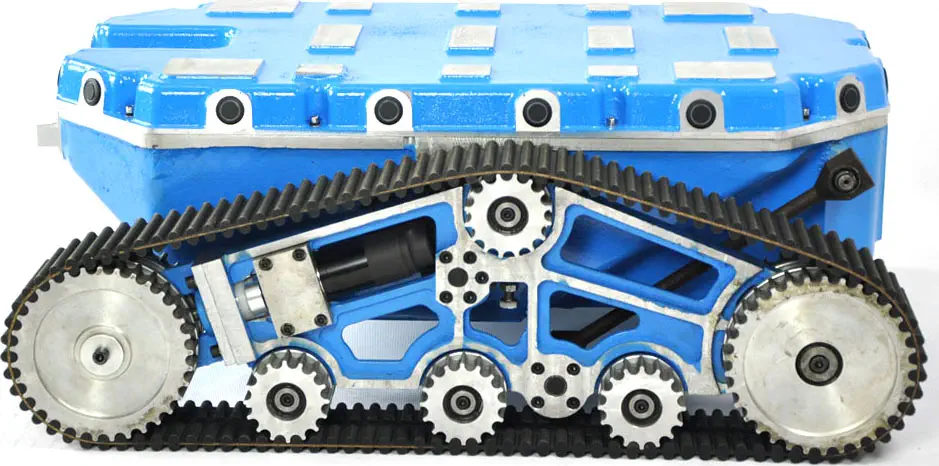

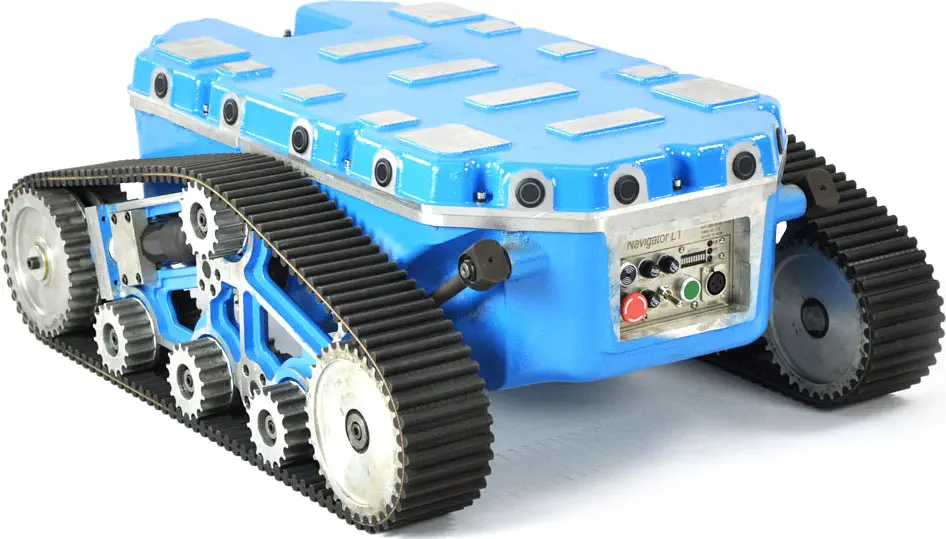

- Body Structure: aluminum alloy molding whole shape

- Driving Wheel: crawler wheel

- Drive Mode: crawler wheel driving with two motors

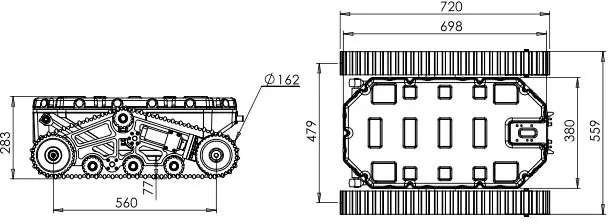

- Minimum Space Between Robot To Ground: 77mm

- Rated Load Capacity: 80kg

- Rated Power Of The Motor: 150W

- Quantity Of Motors: 2

- Maximum Translational Speed: 0.8m/s

- Minimum Turning Radius: 0m

- Typical Duration Time: >8h(load capacity 10KG,moving speed 1m/s, moving rate70%)

- Support Electricity Output: 5V@5A / 12V@5A /battery voltage(35.2~46.2V)@>10A

- Battery Capacity: 24V/18.2Ah lithium-ion battery

- Battery Charger: charger input voltage:AC100V~240V Charging current:5A Interface: direct plug-in

- Accessories: battery charger

- Dimension: 720*559*283mm

- Diameter Of Driving Wheel: 162mm

- Suspend Kind no suspension

- Gross Weight: 45kg

- Motor Type: coreless DC servo motor

- Motor Encoder: 500 line/rev, A、 B phase output

- Motor Driver: servo driver, supporting both CAN bus and RS232 interface

- Maximum Rotation Speed: 95°/s

- Adaptive Ground: indoor, bituminous ground ,concrete ground with little depression

- Standby Time: >30h

- The Default Specification Of The Power Of Insurance Tube: 5×20/20A

- Battery Fast Change: support

Application & Research

- Pattern recognition technology research

- Electronic engineering experiment

- Carrying and storage applications

- Route planning technology research

- Mechanical engineering experiment

- Monitoring and investigation application

- Automatic driving technology research

- Embedded system development and experiment

- The robot competition

- Sensor technology research

- Image process technology research

- Mapping application

- Artificial intelligence research

- Multi-robot cooperation technology research

- Flexible manufacture system application