- DOBOT MG400 Robotic Arm

- Offers a lightweight, user-friendly desktop robot

- Provides multiple controls for beginners & professionals

- Equipped with servo motors

- Produce repeatability up to ±0.05 mm

- Open ecosystem for compatibility, expandability & scalability

- Compatible with a range of other technologies

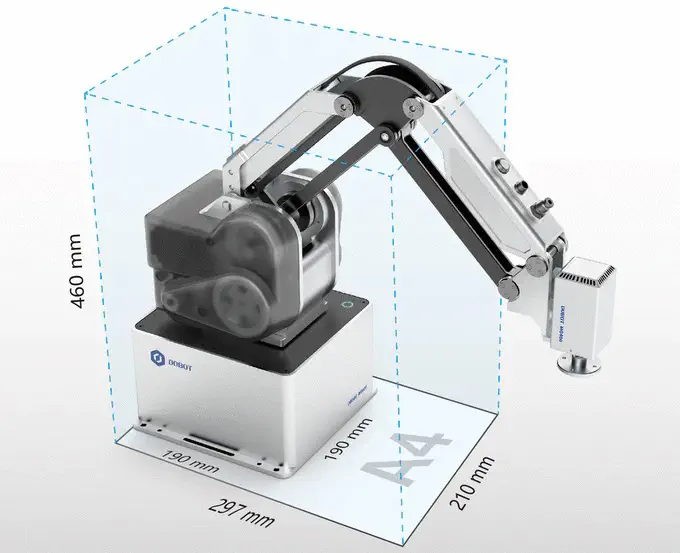

The DOBOT MG400 Robotic Arm is a lightweight desktop robot with a footprint smaller than a piece of A4 paper. Engineered to be lightweight, user-friendly, and safe, MG400 can be easily integrated into any production line or lab bench, making it universally accessible and affordable.

Commercially Available Industrial-Grade Performance

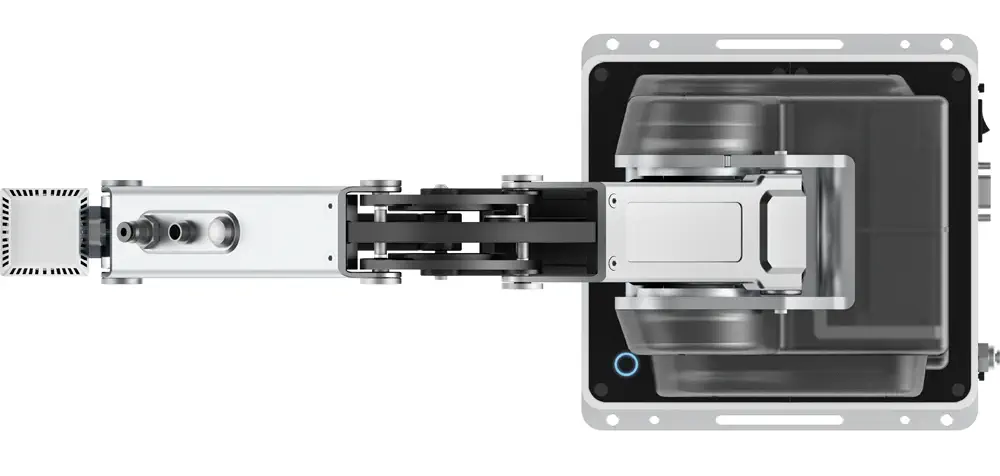

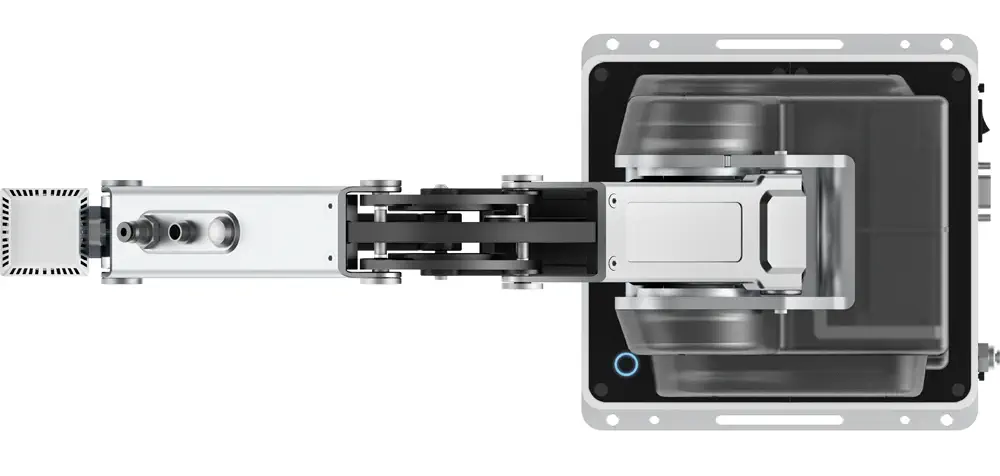

Professional Hardware: MG400 has a controller design based on Linux real-time system, and makes use of the most advanced 1-to-4 servo drive technology.

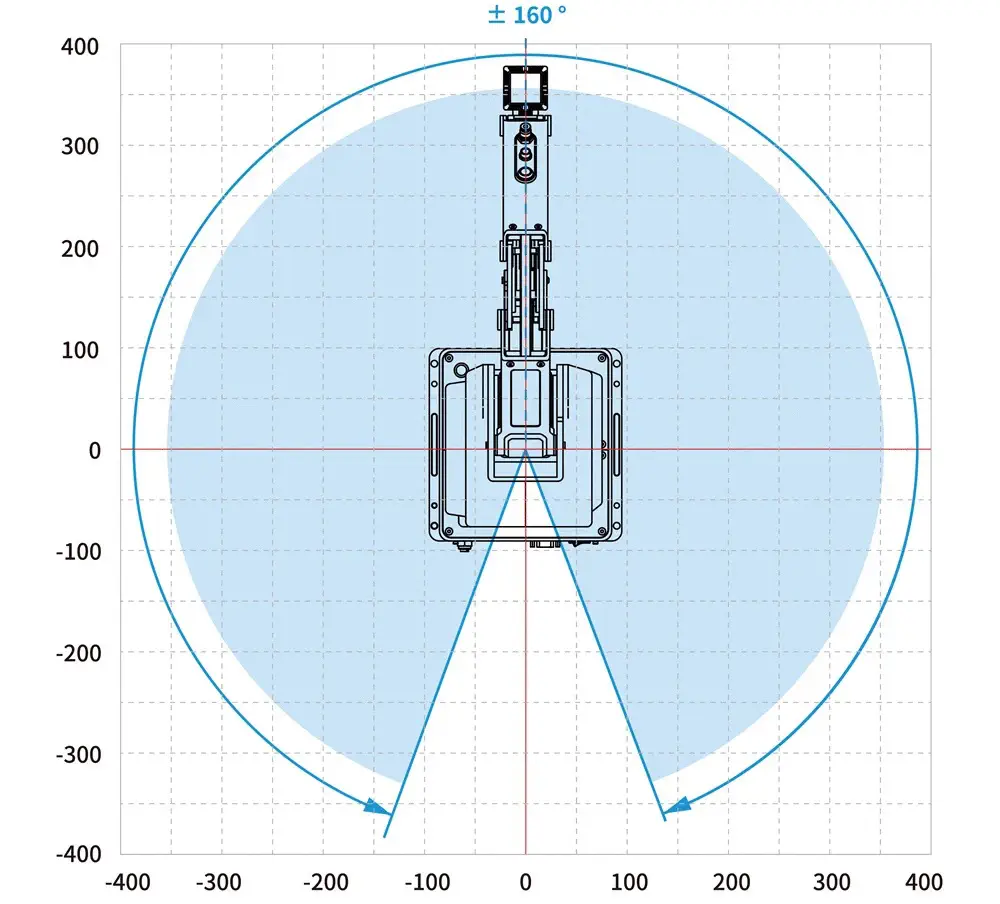

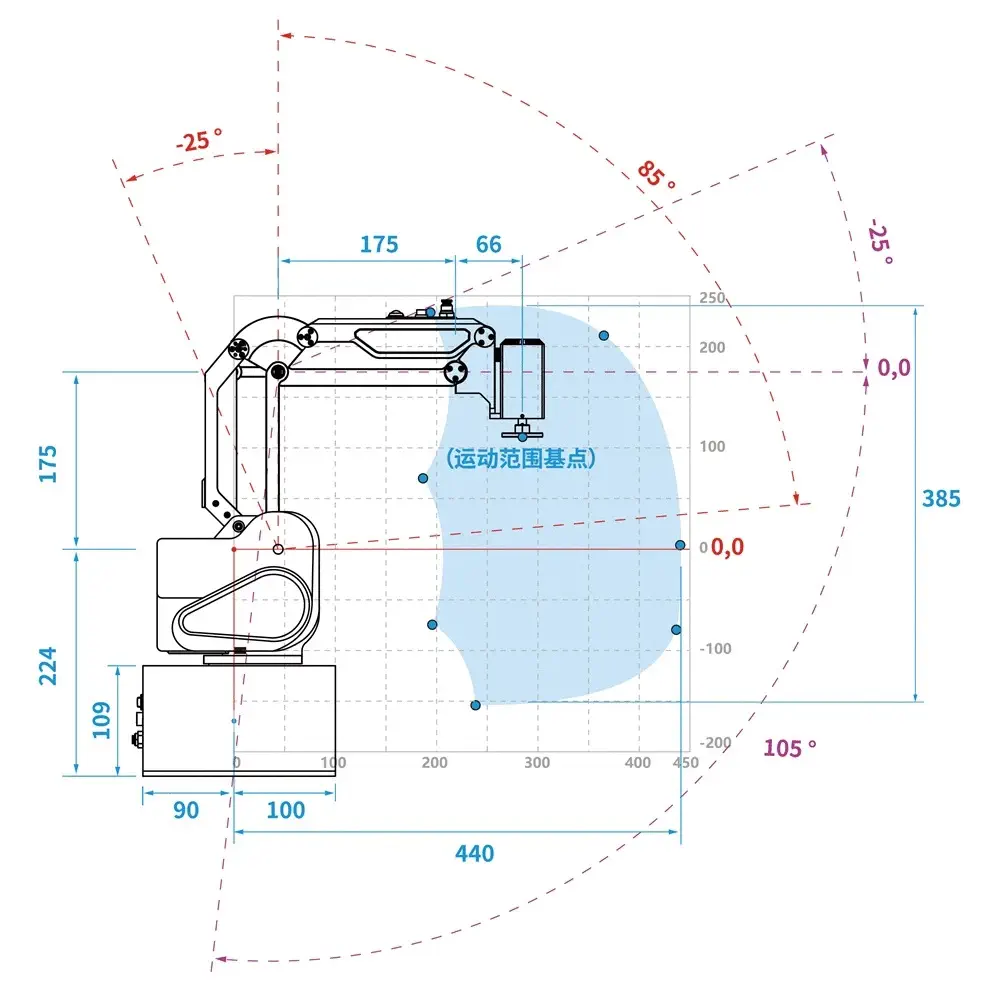

High Precision: All axes use low-voltage DC servo motors with high-precision absolute position encoders and mechanical transmission parts with low backlash. All these put MG400 in a superior position to produce repeatability up to ±0.05mm.

Born for Desktop Application Scenarios

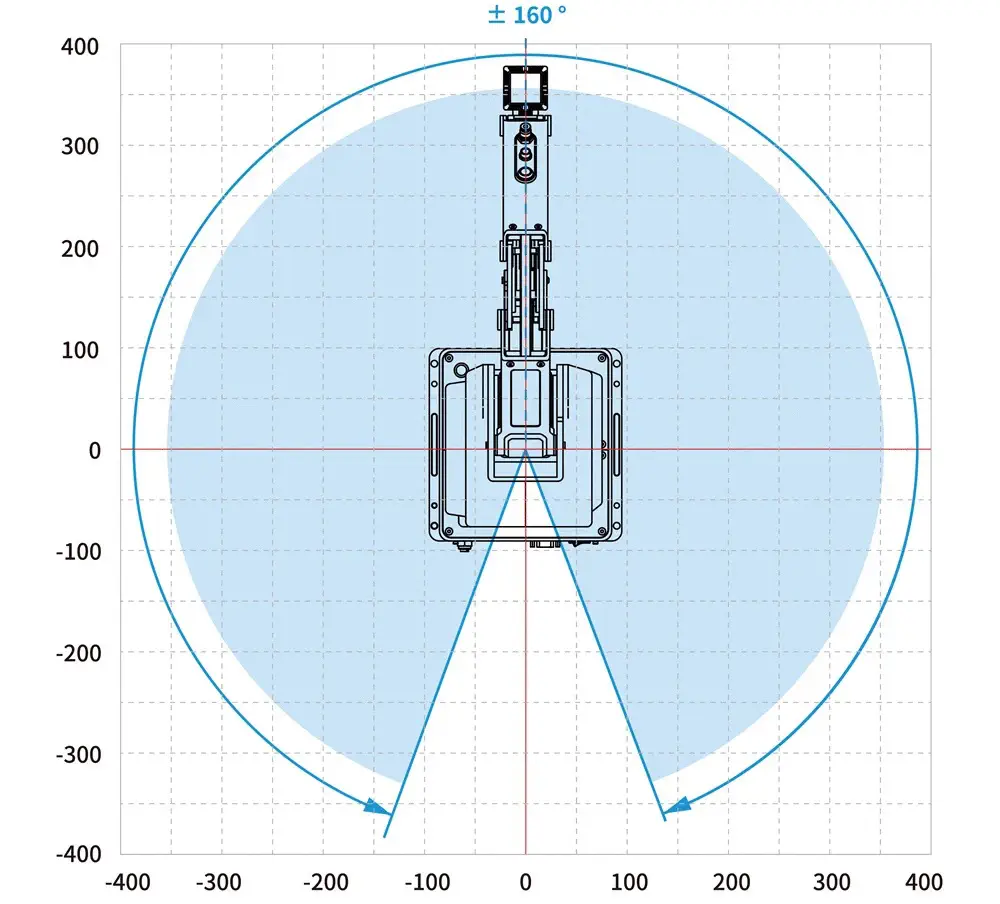

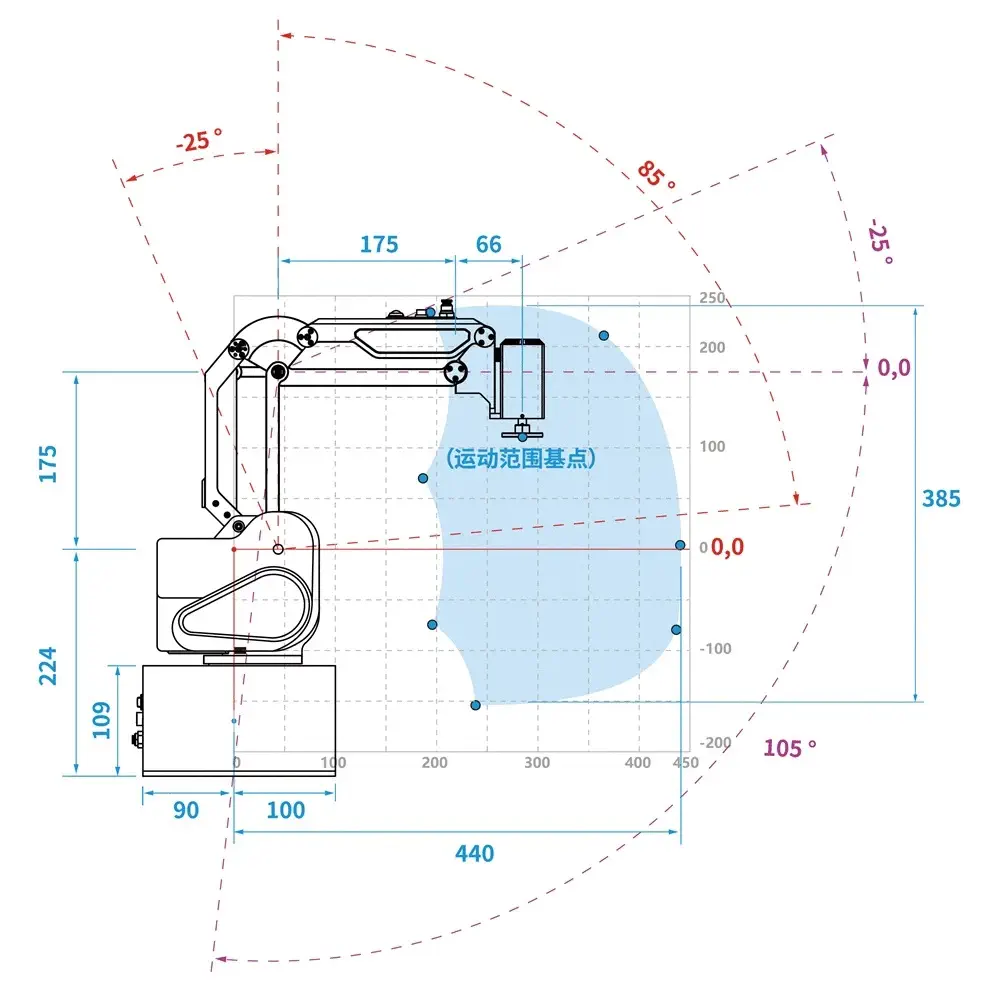

MG400 is designed with small-scale production in mind. With a 190 x 190 mm (7.48 x 7.48 inches) footprint, the robot is lightweight enough to carry in a backpack and compact enough to sit on a desk or workbench as well as alongside an existing production line or cell, offering you full flexibility across your business.

Inherently Safe: So Gentle It Can’t Even Hurt a Balloon

With safety as its core, MG400 adopts an advanced collision detection algorithm with a collision force threshold less than 12N. The robot stops immediately when it touches an obstacle, putting it in the same league as the world’s best robots.

Vibration Suppression Algorithm: Fulfill Tasks Smoothly & Steadily

The adopted vibration suppression algorithm increases repeatability bandwidth stability by 60% and reduces residual vibration by 70% without affecting the space trajectory accuracy of multi-axis motion. This means that the robot’s tool will move more steadily without jittering, ensuring smooth execution of tasks.

TrueMotion Algorithm for Applications Requiring High-Accuracy Trajectory

MG400 leverages TrueMotion Algorithm, a DOBOT-developed technology featuring speed planning and dynamic algorithm. This allows the robot to deliver accurate trajectories at stable speeds, thus excelling in tasks like dispensing.

Teaching MG400 is as Easy as Moving Your Own Hand

With the dynamic gravity compensation algorithm adopted in the robot, first-time users can effortlessly move the robot wherever they like. MG400 will be able to move to these taught with best-in-class precision.

Multiple Controls for Beginners & Professionals

MG400 is programmable through teaching and playback, block program, and LUA scripting, suitable for beginners with no programming experience and veteran programmers alike.

10 Minutes to Get MG400 Up and Running

Install the robot on your workbench, plug-in power, and connect to your PC using an Ethernet cable or to your tablet via Wi-Fi. Lastly, open up our software and the MG400 is ready to go.

Open Ecosystem for Compatibility, Expandability & Scalability

MG400 is compatible with a range of other technologies, making it suitable for advanced and complex applications. With the support of TCP/IP and MODBUS TCP, the robot can be connected to a wide range of technologies.